Improve the pitch system on your Suzlon S88

Poor cabinet build quality is a frequent cause of Suzlon S88 downtime because of moisture and vibration issues. Opting for a retrofit pitch control solution not only solves the immediate problem through better cabinet quality; it also offers a number of additional benefits such as optimised pitch control and full data access while making you independent of expensive OEM support.

The pitch system on any wind turbine is very important for optimising power production. In addition, it is the most important safety subsystem on the turbine, allowing it to stop in high winds or other unfavourable operating conditions. On the Suzlon S88, however, the pitch system has sometimes been a source of turbine failure; not so much because of the pitch system itself as the cabinet housing the pitch control system.

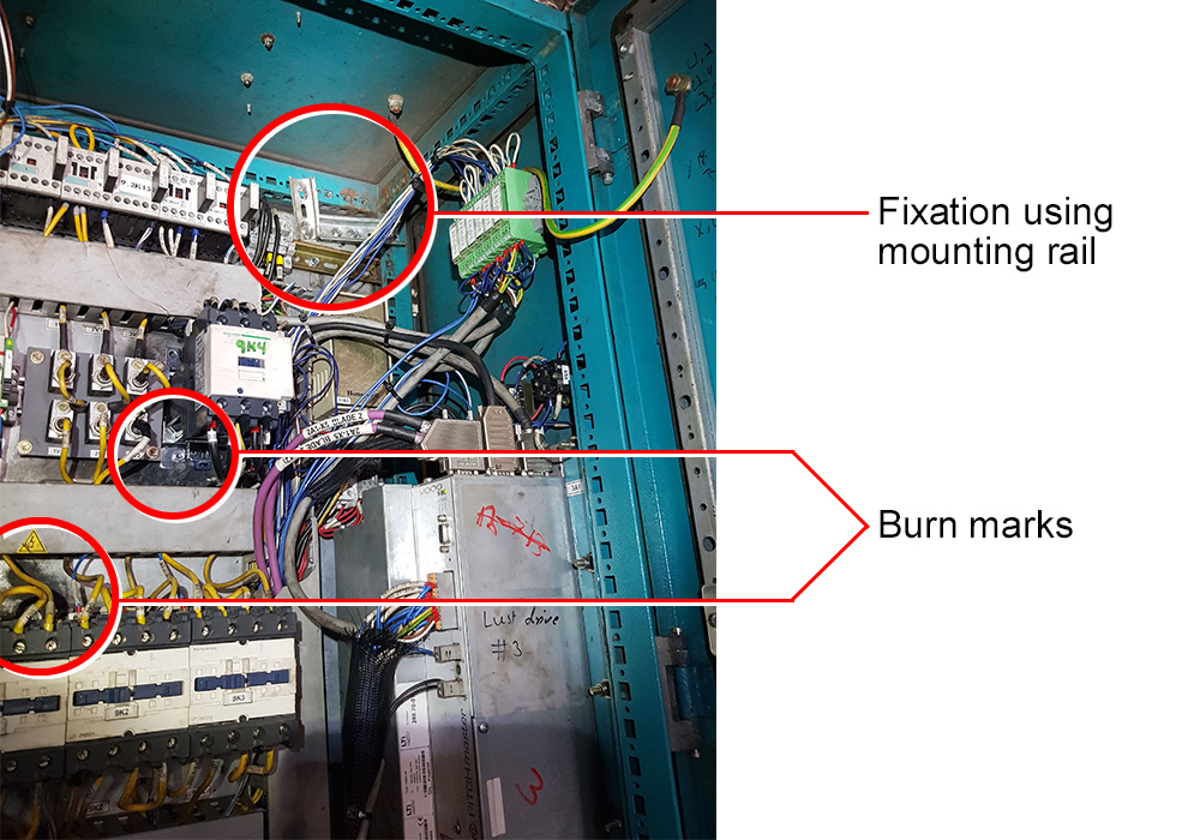

The poor build quality of the S88 pitch control cabinet means that moisture can enter the cabinet, causing short circuits and component failure. On some S88s, short circuits have resulted in burns inside the cabinet. Also, on at least one occasion the cabinet mounting plate was fixed with a mounting rail, increasing vibrational stress on the cabinet components and further aggravating the risk of component failure.

Limited reporting and monitoring options

Issues such as these can result in expensive wind turbine downtime. The situation is further worsened by the fact that with the OEM controller, you have limited reporting and monitoring options. You know that the turbine is down, but you do not know why. To find the cause of the problem, you are dependent on OEM support which often comes at a significant hourly fee. Until the problem is identified and solved, the turbine is wasting valuable production time – sometimes for months!

Retrofit: an attractive solution with several additional benefits

In cases such as this, opting for a retrofit pitch control system from another manufacturer is an attractive solution. A third-party pitch control system with better cabinet build quality solves the immediate problem by preventing moisture and vibrational stress from adversely affecting the pitch control system. In addition, the new control system will often provide several additional benefits such as more accurate pitch control, better suitability for MW scale production, and a wider operating temperature range.

Equally importantly, it can also empower you to carry out service and maintenance on the pitch control system yourself, or outsource it to a third-party ISP as required. With detailed error messages and full logging access, you are no longer dependent on OEM support and can take full control of all service activities. You may also have more options for interfacing with SCADA systems or similar, letting you take full control of your wind farm.

In short: With a retrofit pitch control solution, you not only solve immediate mechanical problems that threaten to put your S88 out of production; you also get a host of other benefits that can improve power production and give you better options for monitoring and troubleshooting your turbine.

Read more about pitch control retrofit solutions from DEIF

DEIF offers pitch system designs for all major turbine brands. Read more here

-

Contact us to discuss your options

- 90 years of energy pioneering

- Manufactured at the highest standards

- Superior quality

- Unmatched service and support

- Made in Denmark