Protection & power management (PPM 300)

The marine and offshore industry faces many challenges in terms of cost, space, efficiency and reliability. When investing in products and systems which monitor and control critical infrastructure such as generators, customers need the assurance that the products can meet these challenges not only from an initial design and installation perspective but also for long-term service, maintenance and upgrades. For customers who are seeking a cost-efficient, yet flexible, standalone power management and generator control solution, DEIF’s innovative PPM 300 product is a versatile and intelligent solution which is specifically designed to meet these challenges.

No PLCs required – integrated intelligent power management

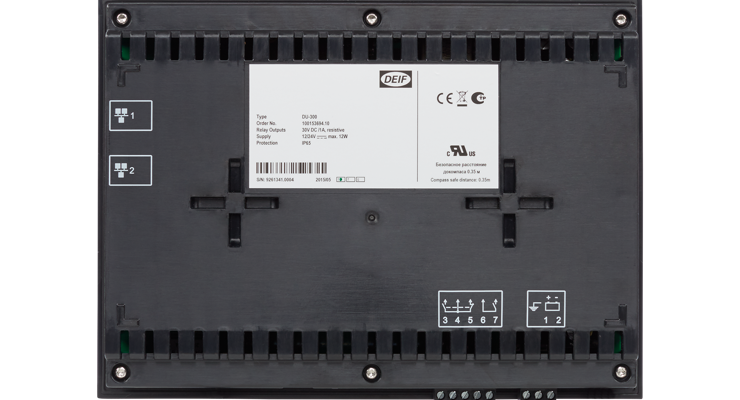

The PPM 300 does not require the use of external control devices such as PLCs, saving time and costs in PLC programming, design and installation. However, its flexibility still allows for the use of external control inputs which can be prioritised, making the PPM 300 perfect for new builds and retrofit applications. No big investment costs are needed for training to set up and use the PPM 300. Designed to be simple and user-friendly, the display unit includes a 5” colour graphic screen with intuitive menus and logical sequences and icons, making it easy to configure and set up and perform maintenance and upgrades. Fast readout of live data and easy access to alarms handling allow quick and efficient use in day to day operations. Design documentation, configuration, commissioning and changes are simplified by using DEIF’s PICUS free PC software. This time-saving supplementary package can create a single-line diagram for the system, and configure the inputs, outputs and parameters for all the controllers and offers emulation, supervision, and management of permissions, backups and firmware updates.

Protecting critical infrastructure

Maximising uptime and protecting assets are concerns that are addressed by the PPM 300’s advanced feature set. By taking advantage of the multi-master capability, multiple PPM 300 controllers can be connected redundantly to communicate as a ring to eradicate single point failures. For example, in cases of a unit fall-out, the master functionality automatically moves to another host, keeping the system not just operational but safe and reliable at all times. Likewise, the PPM 300’s redundant breaker feedback feature allows multiple controllers to communicate their breaker status with each other, preventing a single point of failure causing a costly shut down of the whole vessel power management system.

Advanced functions for a greener world

Leveraging the flexibility of the PPM 300 saves investment and maintenance costs since the PPM 300 can be configured for a wide range of different applications, thus alleviating the need to have multiple products or vendors. An extensive range of protection, supervision and advanced control functions, including market-leading fuel optimisation technology, are provided for a wide variety of applications. Applications range from generator control and protection to engineered power management solutions developed for diesel generators (including emergency diesel generators), shaft generators, shore connections, and bus tie breakers.

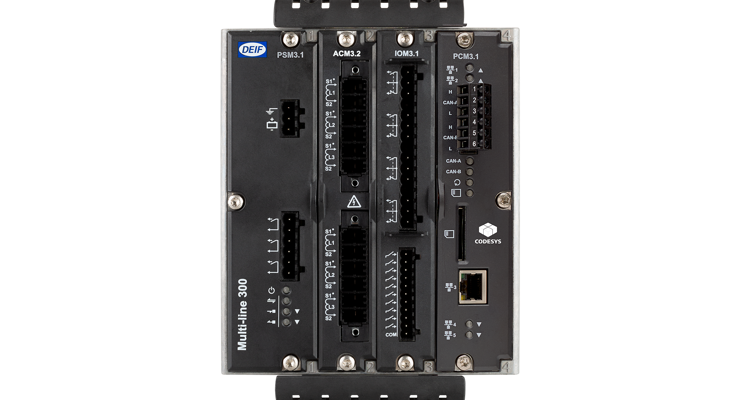

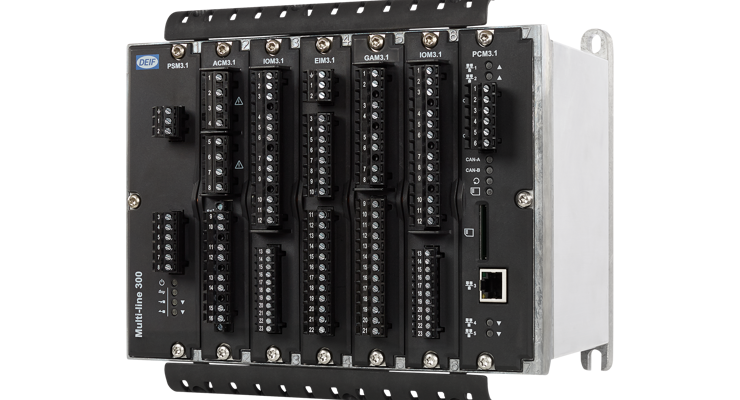

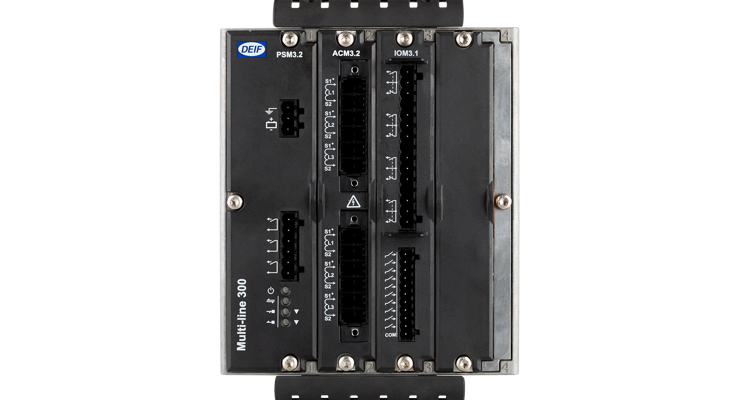

Space-saving, flexible and modular infrastructure

The PPM 300’s cost and space efficiency, flexibility and configurability are thanks to DEIF’s Multi-line 300 platform which offers several different plug-in modules, to meet the varying application requirements. Modules are installed in space-saving 4 or 7 slot extension racks which are expandable with up to 10 racks per controller (1 Primary controller rack + 9 extension racks), giving each PPM 300 controller system support for up to 59 I/O modules. The Multi-line system also provides multiple controller capability allowing the expansion of up to 32 individual PPM 300 systems, giving flexibility and scalability that cater for installations ranging from small vessels to very large power plants. A single PPM 300 can provide ANSI 87G differential protection functionality.

Reduced installation, service, maintenance and upgrade costs

Service, maintenance and upgrade costs are minimised, and obsolescence issues mitigated, thanks to the intelligent modular design which supports easy replacement on board, assisted with automatic functionality recognition. Combined with the unique broadcast feature which allows easy broadcast and replication of single or multiple parameters across multiple controllers, significantly reduces the installation, commissioning and upgrade times and operationally makes changing frequency and voltage for differing shore connections a simple task. Upgrades/retrofitting is made easy with Flexible Modbus, allowing users to customise their own Modbus Tables plus exporting and importing capability.

Type Item number

PPM-300 2911500040

-

Contact us to discuss your options

- 90 years of energy pioneering

- Manufactured at the highest standards

- Superior quality

- Unmatched service and support

- Made in Denmark

Product videos

Products

Installing the display unit (DU 300)

Introduction to the display unit (DU 300)

Introduction to the PPM 300 controller rack

Protection and Power Management (PPM 300)

Unboxing the display unit (DU 300)

Unboxing the PPM 300

Tutorials

Installing the Multi-line 300 controller rack

Cases

Ferry saves 30 % on fuel consumption